The Only Guide to 24??media

Table of Contents24??media Can Be Fun For EveryoneSome Ideas on 24??media You Need To Know24??media - The FactsFacts About 24??media RevealedIndicators on 24??media You Need To Know

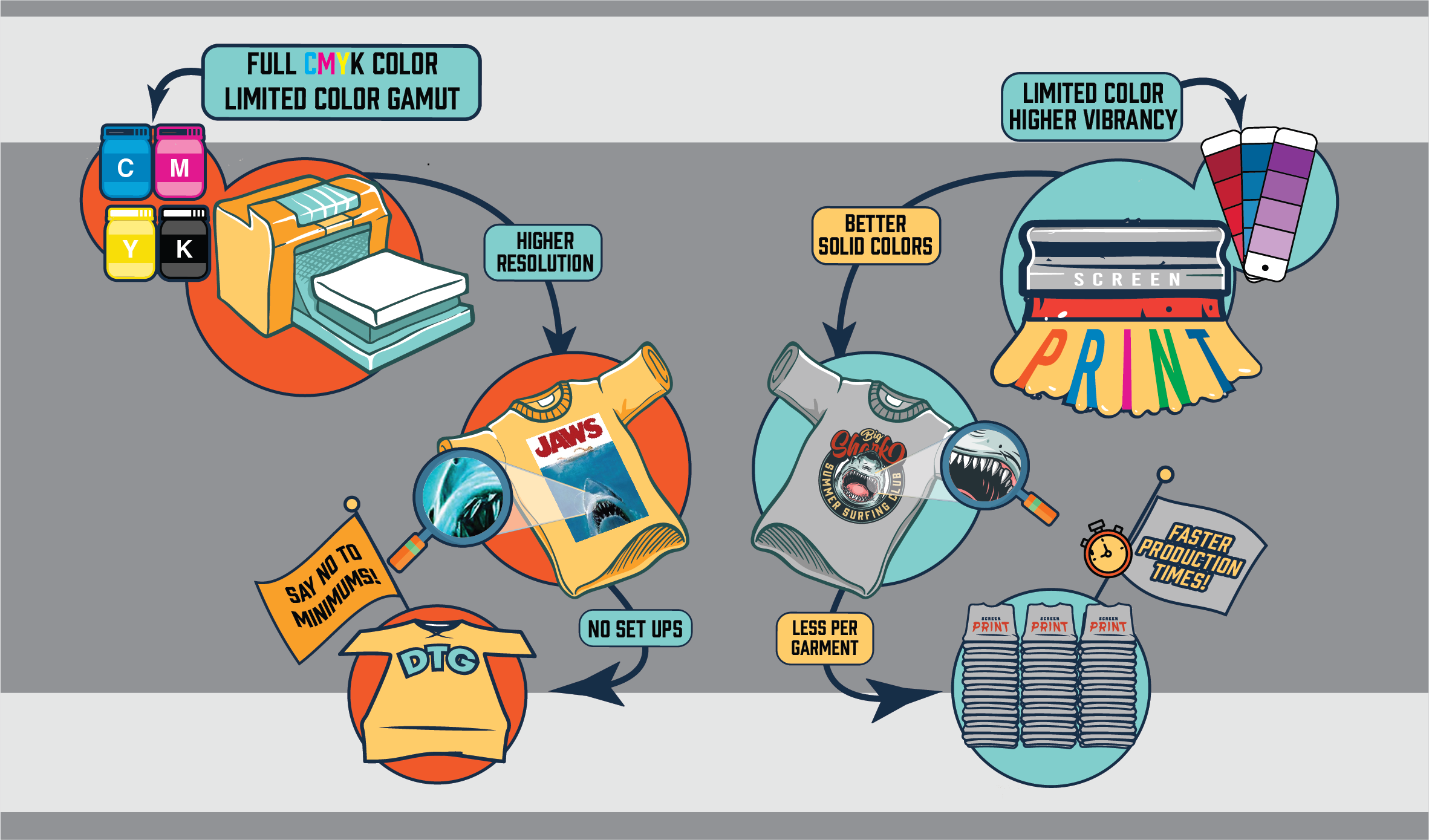

Innovations in print modern technology are altering the interactions playing area when it involves high quality, price and advanced capacities. Offset printing and electronic printing are the significant processes by which print jobs are undertaken both making use of four-color printing methods. Each choice has its benefits, offering different methods to fulfill the demands of diverse production jobs.

Typically, this has actually been the most regular method for specifically maintaining color matches, making it suitable for print runs that only need static printing such as pre-printed types, brochures, flyers, calling card, and mass postcard mailings. However, because of the fixed nature of litho printing, it is not optimal for variable print items that will be mailed to specific recipients such as declarations, letters, and personalized postcards.

How 24??media can Save You Time, Stress, and Money.

The most recent advancements in print modern technology are assisting to bring much of offset's benefits into the digital printing globe genuinely transforming the face of modern-day printing! There are some key differences between Offset Printing and Digital Printing (Digital Printing). This overview shows the advantages and negative aspects of each printing approach. There is an undeniable and growing number of benefits to making use of the digital print process.

Today's digital print devices is amongst one of the most advanced on the marketplace. Here are several of the greatest benefits of making use of electronic printing: dominate the electronic print area, with full-color printing completed in one procedure and effortlessly printed directly from a print documents. Without a prolonged set up procedure, the calibration time of a particular work is shortened, contributing to quicker print time and overall shipment.

The inkjet printing procedure has aided to reinvent the industry as well as the quality and speed of the outcome. The most up to date inkjet modern technology can publish on conventional balanced out supplies with boring, silk, and shiny finishes. High-quality digital print paired with software-managed color administration techniques includes maximum value to publish pieces and makes production procedures a lot more dependable than balanced out.

Little Known Facts About 24??media.

(https://www.giantbomb.com/profile/za24media/)

Environmentally friendly and eco-friendly inks and printer toners are likewise readily available for more sustainable printing. Digital print additionally removes the requirement to clean plates or coverings with damaging chemicals at the end of the printing procedure.

Variable data assists services Full Article reach their precise clients and target market with uniquely-created and individualized material. As modern technology boosts, the top quality of digital printing has actually come to be second-to-none, with better information, shade match capacities and total precision. Without the need to clean plates or make use of excess ink, electronic printing is also less wasteful and normally much more eco-friendly.

("flexo"), include multiple make-ready steps to move an initial image to a substratum.

The 30-Second Trick For 24??media

Digital printing, with fewer moving items, is more agile than balanced out in this respect.

Minimized set-up time conserves money on the front end. And considering that these are not massive bulk orders, smaller organizations can afford to print without having to satisfy the greater and extra expensive print thresholds of conventional printing.

Be certain you team up with a printing and packaging partner that has the best accreditations. While eleventh-hour printing and modification are a huge advantage, electronic may not always be the most effective method for you. Offset printing has the benefit of cost-effectiveness with large print runs, especially those with advanced decorative effects and specialized coverings.

8 Easy Facts About 24??media Described

Lithographic presses use 2 print platesa favorable and a negativeto transfer premium color graphics onto an ideal substrate. The positive plate, with its smooth surface, attracts oil-based inks and drives away water. In contrast, the negative plate, with its rough texture, takes in water and pushes back oil. Rubber rollers are after that made use of to transfer the image from home plate to the corrugated surface area.

Corrugated paper can occasionally confirm to be a tough surface area to publish on, yet Litho prints to a different surface and is then laminated to it, making it easy to publish high-quality photos. It can be exceptionally regular, also for long terms. As a matter of fact, the much more you publish, the more affordable the expenses come to be for Litho.

What Litho doesn't offer you is precisely what Digital does, personalization. Expensive established up Longer turnaround No Variable Information Printing Smaller shade gamut, shades can be less bright Digital printing is the process of printing electronic photos directly onto the corrugated substrate using a single-pass, direct-to-corrugate strategy.